en

+

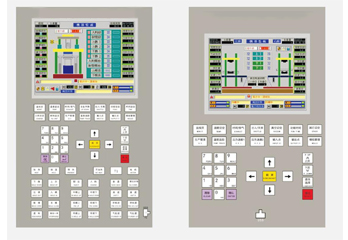

1) 64-bit CPU computer with faster computing speed and accurate positioning of incoming and outgoing molds, ensuring that the molds are not damaged.

2) The electro-hydraulic integrated servo system makes the machine more silent, energy-saving, fast, accurate and has low oil temperature.

3) The flow rate and pressure of each action can be set separately to meet the needs of complex production processes.

4) The fast and slow mold calibration function makes the installation of molds more precise and safe.

Energy conservation and noise reduction.

Fast response and high accuracy.

Fewer heating and low oil temperature.

Save installation space.

Overload automatic protection.

Reduce radiation and interference.

The use of rubber compression moulding machines in industrial and commercial settings offers several benefits. One of the most significant advantages is increased efficiency and productivity. Rubber machines carry out various procedures automatically, faster and more accurately than manual processes, resulting in higher production volumes.

Another benefit of rubber machines is their flexibility. They can be successfully used to custom-make rubber products, giving manufacturers the ability to create high-quality rubber components to specific sizes, shapes, and specifications required by their clients.

Rubber compression moulding machines have also led to increased product quality by altering and optimizing the chemical and physical properties of rubber material. This ensures uniformity and reliability of the products produced and long-term durability of the molded components.

In addition to these benefits, rubber machines have been developed to minimize waste, minimize energy usage, increase safety, and comply with environmental policies. Overall, Rubber machines have revolutionized the rubber industry by increasing production volumes, improving efficiency and productivity, and delivering high-quality products.

Rubber compression molding machines are essential equipment in various industrial and commercial applications. YF POWER, a leading manufacturer of power equipment, produces high-quality rubber machines that are used in the production of various rubber products.

Rubber compression molding machines are designed to cater to a wide range of applications, including rubber injection molding, rubber extrusion, and rubber mixing. YF Power's rubber machine line includes precise and efficient machines that are suitable for producing high-quality rubber products, including gaskets, o-rings, seals, tires, and tubes.

YF Power's machines are designed for use in different industries, including automotive, electrical, and construction, among others. The company's machines utilize modern technology that allows for maximum productivity, efficiency, and accuracy, lowering operating costs and minimizing waste.

Additionally, the company offers customer support, including machine installation and training that aims to ensure users achieve optimal performance and longevity from their machines. Overall, YF Power's dedication to quality and innovation continues to make it a go-to choice for customers seeking reliable and efficient rubber machines.

| No. | Name | Material | Characteristic |

| 1 | Master cylinder | QT500-7 nodular cast iron | After aging passivation, it has good toughness and high tensile strength |

| 2 | Main piston | Chilled white cast iron | Ultra-high hardness, wear-resistant |

| 3 | Upper and middle seat castings | QT500-7 nodular cast iron | After aging passivation, it has good toughness and high tensile strength |

| 4 | Column | HRC55-58 | Medium carbon steel plated with hard engraved treatment, guided by oil-free bearings and equipped with dust seals |

| 5 | Column nut | QT500-7 nodular cast iron | Adopting trapezoidal teeth and a special anti-loosening design |

| 6 | Electric heating tube | Iron cadmium alloy wire | Adopting a multi-stage design for durability |

| 7 | Controller | Industry PC | The dual CPU system has fast response speed, accurate positioning, and precise measurement |

| 8 | Hydraulic system | Electro-Hydraulic Servo | Energy saving, noise reduction, fast response, high accuracy, less heat generation, and low oil temperature |

64-bit computing CPU system is adopted, with short reaction time, accurate positioning, and precise metering.

Support the establishment of a connection management system, which can transmit machine parameters to the main computer and be extracted and used by the management system through the OPC UA communication protocol.

Built-in PID temperature control module, Autocorrection temperature control, SSR electronic output control, no spark, low noise, longer service life than traditional electromagnetic contactor, more accurate temperature control, and centralized monitoring and setting by computer panel.

32-point input, 32-point output, and can be expanded as needed.

6 sets of A/D ratio inputs, and 4 sets of D/A ratio outputs.

10 "LCD color LCD screen runs at a speed of 300MHz. The memory is 16Mbytes, automatically storing production parameters in the computer every second, facilitating production quality traceability and control.

Button operated, USB external interface, standard Chinese and English bilingual operation.

240 sets of parameter storage.

One-week preheating function.

Operation-level and system-level secondary operation passwords facilitate production quality control.

Find Quality Surge Arrester, RTV Antifouling Coatings,Compression Moulding Machine, MOV Blocks, Composite Insulator, Silicone Rubber for Electric, Drop Out Fuse Cutout Switch, Distributed Fault Location System For Overhead Lines from YF Power.